Pipeline Integrity Assessment Applications By Using Vibroacoustic Technology

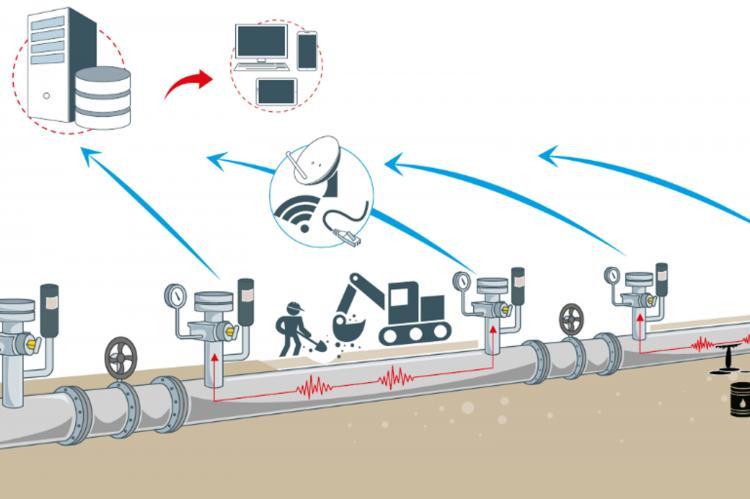

Asset integrity and operation reliability are primary objectives in pipeline management, nevertheless they require often costly methods, system and procedures. The vibroacoustic technology, developed by Eni S.p.A to detect impacts and spillages on Oil & Gas pipelines, already proved to be able to detect illegal tapping precursor events, and recently also to be capable of performing tasks related to integrity assessment.

From a physical point of view, each event or anomal y able to generate a perturbation of the vibroacoustic wave-field into the pipeline can be detected and localized. These kinds of perturbat ions can be clustered in three main sources. As a Primary one, we mean all the sources of acoustic noise pro duced by a direct or indirect interaction with the fluid, such as spills, impacts, the formation of degassing bubbles, valve handling/regulations and the jet noise generated by pre-existing breaches.

As a Secondary one, we mean all the signals produced by the interaction of the pump noise or the spill itself (primary sources) with all the geometrical or mechanical anomalies of the duct. The processing and interpretation of these secondary signals is quite complex because of the use of special processing techniques. As a Mixed one, we mean all the noise sources combining the joint effects of primary and secondary sources, such as a PIG (Pipeli ne Inspection Gauge) travelling into pipeline. In these cases, an analysis of simple pressure data is not enough to provide a correct interpretation of the recordings involved, but efficient and real-time algorithms are required because of the transience of the phenomenon.

By advanced software plugins and system scalability, the e–vpms® system proved to be successfully usable as a digital integrated platform. Additional information gathered using vibroacoustic sensors can be enhanced and automated for the pipeline integrity assessment, with advantages on operational efficiency.