Calculation of a laser-scan-like 3D defect profile from conventional MFL data

Calculation of a laser-scan-like 3D defect profile from conventional MFL data – For more-accur ate defect assessment and prediction of safe operating pressure.

Reliable pipeline safe pressure prediction is increasingly required. Complex shaped volumetric metal loss is a challenge in this regard. Methodological In-line Inspection (ILI) restrictions and p rincipal reporting simplification reduce the precision of ILI results and output tables. Today, phenomenological Magnetic Flux Leakage (MFL) data parameterization is rearranging complex metal loss structures and often results in reduced accuracy. Nevertheless, the established maximum depth boxes do not necessarily prevent case s where MFL data interpretation is insufficiently conservative.

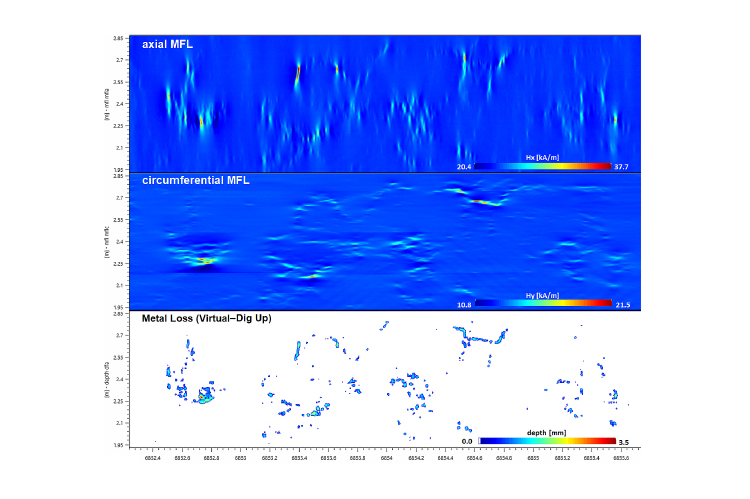

The presented ground-breaking MFL data evaluation technique directly calculates the accurate 3D metal loss geometry as an alternative to the currently practiced boxing. The resolution of the innovative result opens a new dimension for MFL. Auxiliary components of the typical MFL indirect interpretation method lose importance with this new system. Experience-based practices using human expertise, artificial intelligence or elaborate sizing models play a role still, but the conclusive accuracy of the calculated metal loss profile becomes significantly independent from the variability of these experience-based practices. This technolog y enables new services for difficult-to-access areas, areas with complex corrosion, or instances in which a laser map cannot be obtained, resulting in a more accurate, reliable and detailed corrosion growth assessment. This paper will detail concrete case examples from blind tests with high-resolution laser maps and will compare the new approach with results from the traditional MFL evaluation. Performance and reliability analyses help rationalize this innovative technique and demonstrate the contribution to more reliable management of metal loss threats. As part of describing this new evaluation technique, theoretical and practical advantages will be discussed of combining axial and transverse MFL measurements for detection and sizing of metal loss anomalies.