Digital Pipeline Integrity with Spiral Wound Pipe

Interest in using digital systems for pipeline integrity management are growing and the potential both for cost saving on time based manual inspection and for improved real time data is huge.

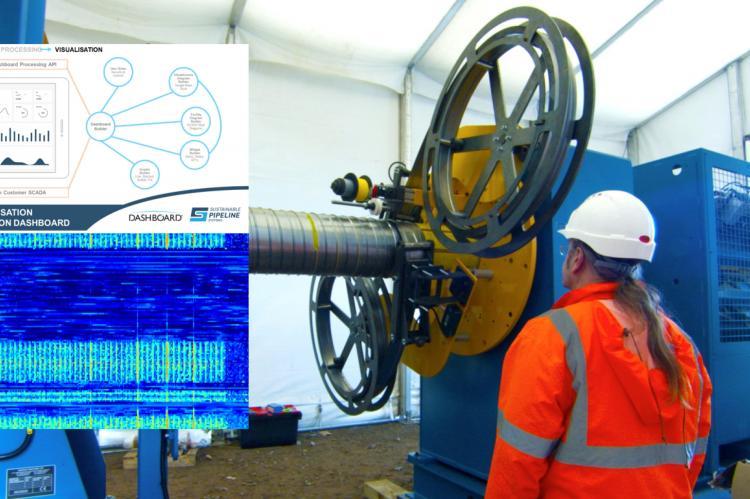

A onshore new pipeline system, MASiP, (Mobile Automated Spiral Interlocking Pipe) has been developed that incorporates spiral wound optical fibre as a means of providing an enhanced l evel of real-time information about stressstrain patterns in the pipe, together with pipeline integrity issues as a result of internal and external inputs. The pipe structure consists of a polymer liner and reinforcing layers of high strength steel strip with a patented interlock. The whole pipe is then coated for environmental protect ion. This type of pipe structure is inherently more flexible and more responsive than conventional steel pipe structures.

This pipeline system, MASiP is designed to be manufactured in t he field with advanced QC systems ensuring good information about the initial status of the pipe. 12-inch diameter p ipe has been fabricated and tested at pressures up to 100 barg with water media and with hydr ogen rich natural gas mixtures. Pressure fluctuations in the range of 30 to 40 barg have been used to calibrate the system.

Outputs from the spiral wound optical fibre windings have been analysed using DAS (Distributed Acoustic Sensor) electronics. These outputs enable a healthy pipe pattern to be characterised to a resolution of about 6 inches along the pipeline length and then continuously monitored. The methodology under development aims to go beyond leak detection and use the information within a comprehensive life prediction methodology.

This approach is designed to enable pipeline operators to have a real time view of the pipeline with a cumulative estimate of residual life. In this way maintenance can be preventative and leaks avoided providing a more proactive approach to pipeline integrity compared to current methods.

MASiP is designed to be a genuinely sustainable pipeline system with an intrinsically digital infrastructure for pipeline integrity management.