Know Your Deposits – Novel Deposit In-Line Inspection Tool For Quantifying And Characterizing Solid Deposits

Pipeline pigging services in the oil & gas industry are of considerable mar ket size estimated to reach more than 14 billion USD by 2025. It is essential for the operator s to keep the lines open for smooth flow and the intelligent services are in focus to increase efficiency and cut the overall operational costs. Optimal pipeline cleaning requires exact knowledge about deposit types, thicknesses and build-up locations in the pipeline. This information allows maximizing production throughput and optimizing the usage of chemicals as well as cl eaning pig programs from the number of runs needed to the sizes used.

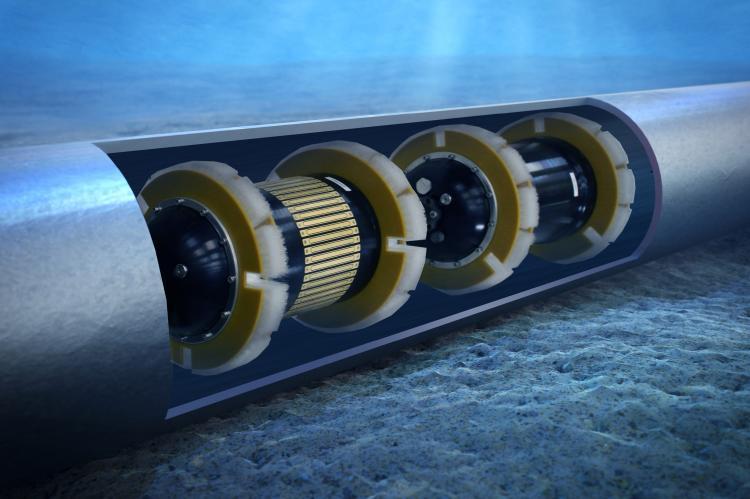

Rocsole Ltd has been developing deposition in-line inspection (DILI) tool based on electrical tomography. This technology is already being utilized for other oil and gas ap plications. This tool quantifies and characterizes solid deposits in piggable liquid and gas flow l ines and pipelines. Current tool sizes cover pipeline sizes between 8”-28” with minimum 1.5D bends and maximum pipeline length of more than 100 km. The risk of the tool becoming stuck in the pipe is minimized since the sensor diameter is significantly smaller than the pipe diameter (tool is non-aggressive). The tool uses safe and cost-effective non-nuclear technology t o measure the solid deposit thickness and t ype while traveling through the pipeline along with the flow without production shutdowns. In this article, deposit inspection results from different deposits tests are discussed.