Electro Scan: Watertightness Testing of Cured-In-Place Pipe Presentation at ptc

Electro Scan announced that its CEO & Founder, Chuck Hansen, will speak at the 15th Pipeline Technology Conference (ptc) on Watertightness Testing of Cured-In-Place Pipe, March 30 - April 2, 2020 at the Estrel Congress Center, Berlin, Germany. Hansen will present his paper Wednesday, April 1, 2020, titled "Use of Low Voltage Conductivity to Conduct a 10km Inspection of Legacy Cured-In-Place Pipe (CIPP) for a Leak Assessment Project."

A leading subject matter expert on pipeline condition assessment, Hansen is former Chair of ASTM Subcommittee F36.20 Inspection and Renewal of Water and Wastewater Infrastructure. Hansen also developed the first widely-used Closed-Circuit Television (CCTV) coding system for sewer condition assessments in the U.S., used by nearly 1,000 agencies worldwide.

Prior to founding Electro Scan Inc., Hansen was CEO & Founder of Hansen Information Technologies Inc., a leading provider of sewer & water asset management and condition assessment solutions. Founded in 1983, Hansen sold the company to Infor Global in 2007 for US$100 million.^Now, an impact investor supporting measurable environmental and clean tech investments, Hansen is also an investment adviser to a leading California-based venture capital firm.

"Utilities are facing a trillion-dollar price tag to fix and upgrade critical sewer & water infrastructure, but a majority of engineers and contractors typically perform construction reviews using inherently limited visual inspection techniques to 'test' and 'accept' projects," stated Hansen. Academics, engineers, and industry consultants have long recognized the limitation of using CCTV cameras to inspect the condition of existing, recently rehabilitated, and newly installed pipelines.

Today, sophisticated robotic cameras are still unable to tell the difference between superficial cracks and cracks that go through a pipe wall. And, Artificial Intelligence (AI) and Machine-Learning (ML) add little to finding leaks that can't be seen due to drawbacks of visual inspection. Given the impact of climate change and associated rising sea levels, utility managers must address the consequences related to more frequent and severe flooding, sewer overflows, and sewer back-ups due to leaking infrastructure.

Salt water infiltration now causes billions of dollars in damage to water pipeline infrastructure and costly delays in deploying badly needed wastewater reuse programs, as well as significantly impacting treatment plant performance and operational burdens in key coastal areas. As the gap widens between 'what' utilities expect from their CAPEX investments and 'how' the market delivers CAPEX projects, the industry is calling for unbiased, unambiguous, accurate, and repeatable pipe leakage reporting to ensure resilient and sustainable improvements to infrastructure.

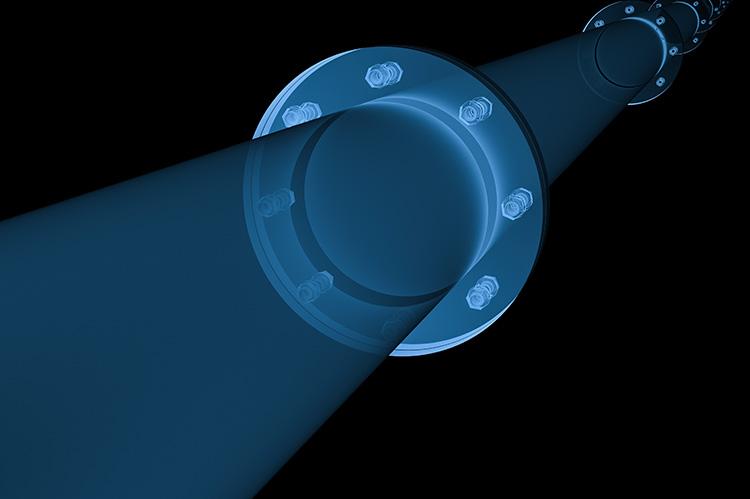

Electro Scan's Focused Electrode Leak Location (FELL) technology represents a machine-intelligent, non-destructive, pipe assessment technology that uses a low-voltage, high-frequency electric current to precisely locate leaks, within 3/8th of an inch (1cm), and quantifies defect severity in gallons per minute or liters per second.