Proliner Pipeline Services providing solutions in the Oil & Gas Pipelines sector - Danny Haykal

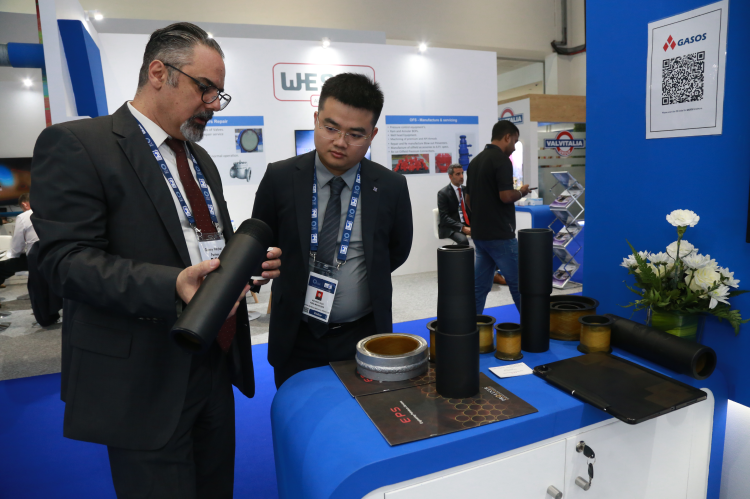

Exploring Innovation in the Pipeline Sector: A Conversation with Danny Haykal of Proliner Pipeline Services, a startup from the MENA region met at ADIPEC 2023

Can you provide a detailed overview of Proliner Pipeline Services' GRE-lined OCTG and its applications? What makes it a superior solution for addressing internal corrosion in pipelines?

Proliner Pipeline Services (PPS) is a UAE established company specialized in GRE Lining solutions in the Oil & Gas Pipelines sector. GRE-lined OCTG is mainly applied to corrosive fluids with high corrosion potential where conventional barrier type films (inhibitors, thin-film coatings) face a high failure probability.

GRE Lining pipes carries many advantages vs traditional pipes:

- Protects against corrosion and abrasion.

- Enhances the lifespan of pipelines.

- Improves flow efficiency and reduces friction.

- Resistant to chemicals and harsh environments.

- Easy to install and maintain.

- Provides the possibility of using used pipes (condition B and C) in various applications

In what specific industries or environments is the Proliner Lining System most commonly used? Are there any notable success stories or case studies you can share that highlight its effectiveness in combating internal corrosion?

PPS lining solutions are targeting applications in Sour down-hole conditions containing H2S and CO2, disposal Wells, water Injector wells, CO2 WAG, SRBs, wells suffer from corrosion due to its high oxygen content, wells suffering from iron sulfide and iron carbonate build up, oil producers with high water cut percentage, and surface flow-lines. Other applications spanning also to offshore platforms, subsea pipelines, desalination plants, refineries, and petrochemical facilities. This application can be applied to used and new OCTG (Cond. A, B and C) and factory defected CRA and CS pipes, and High hoop strength Suitable for both API and Premium connection.

With more than 2,500,000 feet of lined OCTG and pipelines experience, and more than 600+ wells, our studies and field trial show an extended Service Life for the GRE lining pipe vs the traditional pipe. Ensures pipelines last up to 300% longer than a typical design life (5 years vs 20 years), curbing replacement and downtime costs significantly. Imagine the operational efficiency gains!

Internal corrosion in pipelines is a significant concern. Could you elaborate on the key features and benefits of the Proliner Lining System that differentiate it from traditional corrosion mitigation methods, such as inhibitors or thin film coatings?

In the oil and gas industry, strategic choices can significantly impact well performance and longevity. There is a major difference between Standard OCTG with the addition of corrosion inhibitors (or thin film coatings), and GRE Lined OCTG pipes, let us highlight some below:

I. Material Composition:

- Standard OCTG with Corrosion Inhibitors: Predominantly carbon or alloy steel with the addition of corrosion inhibitors.

- GRE Lined OCTG: Steel core with Glass Reinforced Epoxy (GRE) lining, inherently resistant to corrosion. Although standard OCTG with corrosion inhibitors can enhance corrosion resistance, they still fall short of GRE Lined OCTG's inherent corrosion resistance in highly aggressive environments.

II. Corrosion Resistance:

- Standard OCTG with Corrosion Inhibitors: Improved resistance to corrosion when inhibitors are applied(costly solution on OPEX).

- GRE Lined OCTG: Exceptional, intrinsic resistance to corrosive environments, such as H2S and CO2-rich wells. While the addition of corrosion inhibitors can extend the life of standard OCTG, GRE Lined OCTG consistently outperforms in terms of corrosion protection, often with lower operational costs. Also due to utilization for Superior resin system that can withstand high temperature applications up-to 290F and high concentrations of corrosive gases, it will improve Flow Efficiency. Moreover, the cement grout squeezed into the annulus is considered a secondary corrosion barrier that enhances the lining system stability against corrosion: Experience a 15% boost in flow efficiency, translating to reduced energy consumption and enhanced performance.

III. Mechanical Properties:

- Standard OCTG with Corrosion Inhibitors: Retains high mechanical strength, essential for drilling and production forces.

- GRE Lined OCTG: Offers a balance of mechanical strength and corrosion resistance. Although standard OCTG maintains its mechanical strength with corrosion inhibitors, GRE Lined OCTG presents a unique blend of strength and corrosion resistance due to its composite structure.

IV. Applications:

- Standard OCTG with Corrosion Inhibitors: Versatile and can be adapted to various well conditions, with enhanced corrosion protection.

- GRE Lined OCTG: Preferred in highly corrosive environments, delivering consistent, long-term corrosion resistance. The choice between the two is influenced by the specific well conditions and operational requirements. GRE Lined OCTG remains the top choice for environments with severe corrosion challenges.

V. Extended Service Life: GRE lining ensures pipelines last up to 300% longer than a typical design life (5 years vs 20 years), curbing replacement and downtime costs.

VI. Cost Savings: Studies reveal a potential 25% reduction in maintenance costs over the lifecycle of GRE-lined pipes compared to traditional OCTG. Think of smart investments for sustainable profitability!

Could you explain the process of installing and maintaining the GRE-lined OCTG and the Proliner Lining System? What considerations should operators and pipeline owners keep in mind when implementing this solution?

One of the major benefits of utilizing Proliner is that it doesn’t require any special handling or specific modification procedure since Proliner doesn’t require any modifications to the connection and it complies with API RP 15 CLT requirements.

For API connections, we provide elastomeric rubber rings to be installed in the connection area (J-Area) with different widths to provide the flexibility to apply the required API torque values without any restrictions.

For premium connections, we provide PTFE rings that allow for installation into the pipe bore to avoid interaction with the metal seal to make sure that the lining system complies with the manufacturer design and to guarantee that the torque graph and sealability of the connection remain unchanged.

For welded pipelines, Proliner utilizes a proprietary welding sleeve (Patent pending) at the welding area to isolate the heat induced during welding. This welding sleeve is designed and complies with most of the welding procedures for different grades of pipelines.

Moreover, wire-line tools, PLT and coiled tubing have been successfully run through PROLINER tubing strings without damage to the lining system, however there some simple guidelines have to be followed during well intervention if PROLINER is in the well, the intervention tools have to be without sharp edges, intervention velocity should not exceed 100 ft/min., gauge cutters are not allowed for GRE lined tubing intervention.

Given the evolving nature of the energy and pipeline industry, are there any ongoing developments or innovations related to the Proliner Lining System that you would like to share, or any future trends in pipeline corrosion protection that you anticipate addressing with your technology?

PROLINER R&D team is developing a lining system for higher temperature applications that exceeds 300F in addition to another lining process for in-situ pipeline lining instead of joint-by-joint lining.