Trenchless pipeline installations in European key projects

Issue 3/2021 of ptj is the second issue of the Pipeline Technology Journal in 2021

On its 58 pages this issue features papers to the topics of Pipeline Planning & Construction. From a fully-electric driven HDD rig to the use of artificial intelligence during the planning of offshore pipelines. This issue contains 6 papers from different companies.

Issue 2/2021 of ptj is the second issue of the Pipeline Technology Journal in 2021

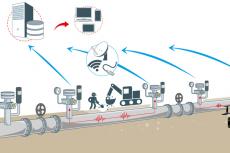

On its 78 pages this issue features papers to the topics of Pipeline Leak Detection & Monitoring. From a case study about the application of Nonintrusive Scraper Passage Indicators to a Pipeline Integrity Assurance System. This issue contains 7 papers from different companies.